railway-international.com

20

'24

Written on Modified on

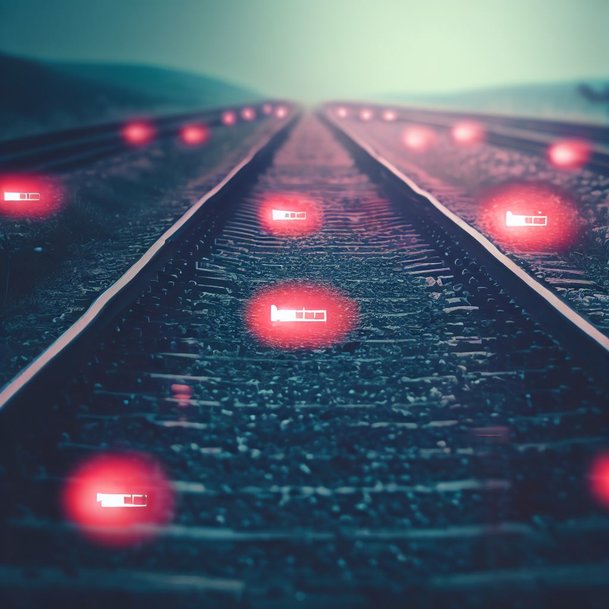

The Sense of a Sensor-Less Railway

This video explores a new approach railway monitoring using “Sensor-less wayside sensing”.

While it might seem like a contradiction, this uses fiber optic cables transforming them into a vast network of vibration sensors through a technology called Distributed Acoustic Sensing (DAS).

I look at why we should consider this, explain how it works, and what kinds of railway infrastructure railway information can be gained. This 30-minute video, originally presented to the Permanent Way Institution, gives an overview of some of the railway infrastructure monitoring challenges as well as how and where fiber optic sensing can help.

I’ve summarised some of the key points below, but for the full detail watch the video here.

Traditional Monitoring Challenges

Traditional methods of railway monitoring rely on physical sensors, which can be expensive to buy, install, maintain, and power. Depending on what you are trying to measure and the area you are trying to measure this may mean many sensors are needed. These sensors are susceptible to both obsolescence over the decades of service life desired for most railways and each one can represent a potential cyber security risk too.

Challenges of Traditional Wired and Wireless Track Sensors

While traditional wired and wireless sensors can play a role in railway monitoring, they come with several significant challenges that sensor-less wayside sensing with fiber optics can overcome. Here’s a closer look at some of these drawbacks:

Wired Sensors:

Installation: Installing wired sensors usually requires trackside access, which can disrupt railway operations and consume valuable maintenance time and resources. The installation of extra cables can clutter the lineside and leave track harder to maintain in future.

Power: In remote areas power may not be readily available meaning remote power infrastructure may be needed to support the installation.

Maintenance: Sensor maintenance can vary depending on the type, but may involve regular inspections, cleaning, calibration and of course repairs, adding to maintenance costs and workforce requirements. Being wired – damage to cables from maintenance activities, vandalism or theft can also be an issue.

Limited Scalability: The wired approach can become impractical for monitoring long stretches of track with many sensors due to the complexity and cost of cable installation and maintenance.

Wireless Sensors:

Power: Wireless sensors typically rely on batteries for power, which require periodic replacement. This can be a logistical challenge, especially in remote locations. Battery replacement requires track access and maintenance resources together with the disposal or recycling costs of the battery waste generated.

Cybersecurity: Each added wireless sensor introduces a potential remote entry point for cyberattack, as wireless signals can be intercepted and interfered with. The more wireless sensors you install the bigger the security challenge can become.

Data Transmission: Wireless data transmission can be unreliable and weather dependant, potentially leading to data gaps or disruptions. Extra supporting infrastructure is often needed to supply adequate signal coverage. Remote interference from intentional or unintentional sources can also render systems unavailable.

These limitations can hinder the effectiveness of traditional sensor-based monitoring systems.

Fiber Optics: A Reliable and Existing Solution

Sensor-less wayside sensing with fiber optics offers a compelling alternative by reducing or eliminating the need for additional trackside sensors and their associated installation, maintenance, and power headaches.

Fiber optic cables are already widely used in railways for communication and signalling. They are reliable, robust, and relatively inexpensive. These fiber cables combined with Distributed Acoustic Sensing (DAS) technology forms the foundation for sensor-less wayside sensing. A key benefit is the simplicity of roll out with a single DAS unit able to monitor 100km of fiber which equates to around 80km of rail route.

How it Works: Listening to the Tracks

Distributed acoustic sensing (DAS) is the magic behind the approach. It analyses light pulses traveling through the fiber optic cable, or more specifically the part of light reflected. Vibrations of the fiber alter the reflected signal. By measuring the change in reflections, the system can pinpoint the location and nature of the vibration. A more thorough description of how DAS works can be found here.

Applications: Security, Landslides, Track Faults, and More

Sensonic DAS technology offers a wide range of applications for railway safety and efficiency. A few railway examples of DAS technology are shown in the video:

Security: Detect people trespassing, digging or tampering with cables.

Landslide and Rockfall Alerts: Find ground movements before your trains do.

Flashover Location: Quickly find the exact spot of a flashover event for faster catenary repairs.

Track Condition Monitoring: Track changes in vibration to find potential problems as they develop.

The Future of Railway Infrastructure Monitoring

Sensor-less wayside sensing with fiber optics offers a simpler and more cost-effective solution compared to traditional methods. It uses existing infrastructure and supplies valuable real-time data for better decision-making.

DAS technology is constantly evolving, with ongoing research to expand its detection capabilities. By utilising fiber optics, Sensor-less wayside sensing offers a promising future for a safer, manageable, efficient, and more intelligent railway network.

To see more on applications of DAS technology from Sensonic see our applications here.

www.sensonic.com