railway-international.com

09

'25

Written on Modified on

Tatravagónka and PJM cooperate on digital train functions

The Slovakian manufacturer includes automatic brake testing and all PJM monitoring functions into its equipment portfolio.

pjm.co.at

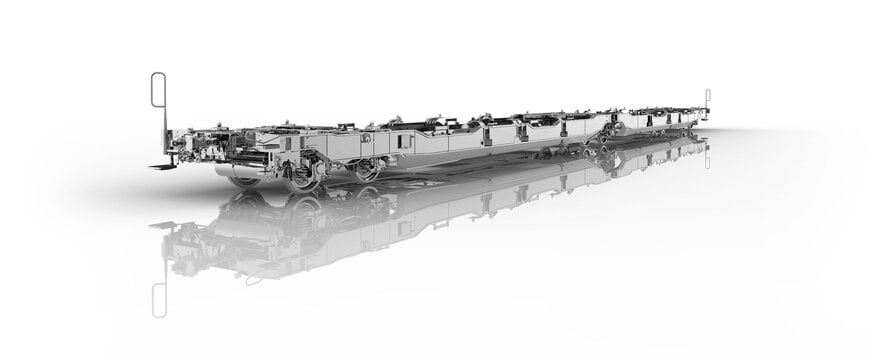

Photo: Tatravagónka

Tatravagónka, the leading freight wagon manufacturer in Europe, is integrating PJM‘s digital freight train functions and automated applications into its equipment range. Hence, the efficiency-enhancing monitoring and automation features are now available ex works for wagon purchasers.

Due to its extensive wagon portfolio, the Slovakian manufacturer is the largest in Europe. Wagon types for the transport of all types of products are developed and manufactured in several plants in Slovakia, including tank and bulk goods wagons, flat wagons, intermodal wagons and steel coil transport wagons. In order to make the benefits of automation and digitalization available to the sector in an efficient way, Tatravagónka is now offering the functionalities of the overall digital system WaggonTracker. The monitoring features include real-time brake analysis and brake system monitoring, real-time kingpin monito ring, IDDS derailment diagnostics paired with real-time in-train communication (direct communication with the train driver), load weight monitoring and automatic brake testing.

The majority of the functions are offered exclusively by PJM, the Automatic Brake Test is the European reference system, with broad support from railway undertakings and wagon keepers. The technical applications create a number of essential benefits: lower costs, higher availability of the goods train, faster train preparation and, above all, greater safety. By ordering ex works, the PJM system is optimally integrated into the freight wagons and delivered to the customer.

With the co-operation with PJM, Tatravagónka is consistently continuing the further development of its product portfolio. The wagons were prepared for automated applications such as the DAC (Digital Automatic Coupling) several years ago. The overall digital system from PJM automates further processes (brake testing and load weight monitoring), which means that the wagon keeper is also ideally equipped for the future: the system is fully compatible with the future digital automatic coupling as well as with other customized applications.

The advantages of PJM‘s intelligent train functions in detail:

Cost savings: The steady and comprehensive determination of specific data from relevant components leads to predictive maintenance and repair planning. Short-term, costly repairs and rolling stock breakdowns are reduced. Time saving: Automatic brake testing and load weight monitoring significantly shorten train preparation times.

Greater reliability: Functions such as load weight monitoring increase the availability of the goods train because loading is carried out more quickly and overloading - and therefore removing the wagon at infrastructure points - is avoided. The kingpin monitoring detects the correct setting of the device.

Gaining safety: All functionalities increase safety. The derailment diagnosis IDDS is equipped with a real-time warning to the train driver, the monitoring of dynamic running status identifies critical running situations and possible faults, the real-time brake analysisand brake system monitoring detects defective and overloaded brake systems at an early stage and the automatic brake test is a safetyrelevant process that determines and checks a wide range of data. Real-time brake monitoring monitors the correct use of the brake system and prevents applied handbrakes.

Today’s advantages and future-proof equipment: The PJM system is scalable and compatible with future DAC solutions and other applications.

Tatravagónka, the leading freight wagon manufacturer in Europe, is integrating PJM‘s digital freight train functions and automated applications into its equipment range. Hence, the efficiency-enhancing monitoring and automation features are now available ex works for wagon purchasers.

Due to its extensive wagon portfolio, the Slovakian manufacturer is the largest in Europe. Wagon types for the transport of all types of products are developed and manufactured in several plants in Slovakia, including tank and bulk goods wagons, flat wagons, intermodal wagons and steel coil transport wagons. In order to make the benefits of automation and digitalization available to the sector in an efficient way, Tatravagónka is now offering the functionalities of the overall digital system WaggonTracker. The monitoring features include real-time brake analysis and brake system monitoring, real-time kingpin monito ring, IDDS derailment diagnostics paired with real-time in-train communication (direct communication with the train driver), load weight monitoring and automatic brake testing.

The majority of the functions are offered exclusively by PJM, the Automatic Brake Test is the European reference system, with broad support from railway undertakings and wagon keepers. The technical applications create a number of essential benefits: lower costs, higher availability of the goods train, faster train preparation and, above all, greater safety. By ordering ex works, the PJM system is optimally integrated into the freight wagons and delivered to the customer.

With the co-operation with PJM, Tatravagónka is consistently continuing the further development of its product portfolio. The wagons were prepared for automated applications such as the DAC (Digital Automatic Coupling) several years ago. The overall digital system from PJM automates further processes (brake testing and load weight monitoring), which means that the wagon keeper is also ideally equipped for the future: the system is fully compatible with the future digital automatic coupling as well as with other customized applications.

The advantages of PJM‘s intelligent train functions in detail:

Cost savings: The steady and comprehensive determination of specific data from relevant components leads to predictive maintenance and repair planning. Short-term, costly repairs and rolling stock breakdowns are reduced. Time saving: Automatic brake testing and load weight monitoring significantly shorten train preparation times.

Greater reliability: Functions such as load weight monitoring increase the availability of the goods train because loading is carried out more quickly and overloading - and therefore removing the wagon at infrastructure points - is avoided. The kingpin monitoring detects the correct setting of the device.

Gaining safety: All functionalities increase safety. The derailment diagnosis IDDS is equipped with a real-time warning to the train driver, the monitoring of dynamic running status identifies critical running situations and possible faults, the real-time brake analysisand brake system monitoring detects defective and overloaded brake systems at an early stage and the automatic brake test is a safetyrelevant process that determines and checks a wide range of data. Real-time brake monitoring monitors the correct use of the brake system and prevents applied handbrakes.

Today’s advantages and future-proof equipment: The PJM system is scalable and compatible with future DAC solutions and other applications.

The whole range of PJM’s smart train features are now available ex works for customers of Europe’s leading wagon manufacturer Tatravagónka

wwwpjm.co.at

wwwpjm.co.at