Not All Presence Sensors Are the Same: Choosing the Right Detection for Your Site

Presence detection is a key part of many Automated Equipment Identification (AEI) systems and yard operations.

www.cometind.com

They detect movement in a specific area or zone, often to trigger the start or stop of a data capture.

But here is the catch: not all presence detection systems work the same way. While motion detection and presence detection are often confused, they are not interchangeable. Motion detection only alerts when something is actively moving, while presence detection confirms that something is in the detection area until it’s not. This is a crucial functionality in the world of AEI, ensuring the capture of full train consist, locomotive to EOT, even with starts, stops, and back and forth movements.

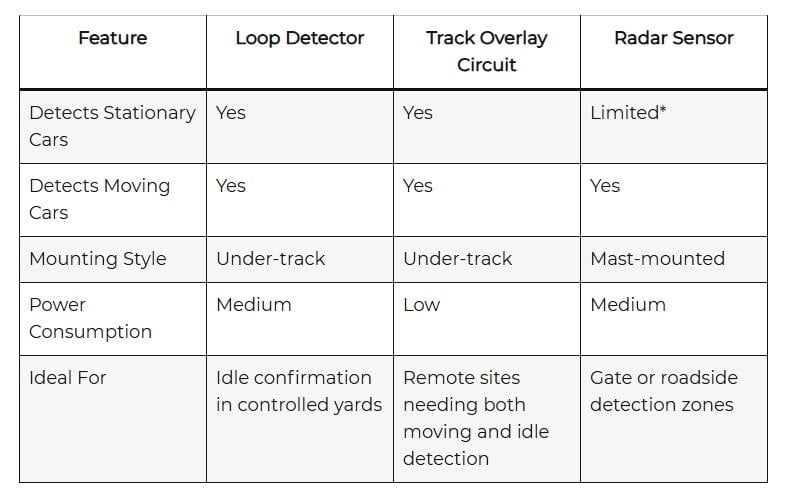

At COMET, we work with three primary types of presence detection technology: Loop Sensors, Track Overlay Circuits, and Radar Sensors. Each has unique advantages and considerations depending on your site conditions, maintenance schedules, and operational goals.

How Presence Detection Works

In rail applications, presence detection means the system can confirm that a railcar is occupying a defined section of track. Unlike motion detection, which signals when an object moves past, presence detection can maintain that signal even when an asset is stationary. This ensures the AEI system starts up and is ready to capture asset data until no presence is detected.

Choosing the wrong sensor type can cause missed reads, false “clear” signals, or unnecessary downtime. That is why selecting the right presence detection for your site environment and operational needs is so important.

The Three Main Types of Presence Detection

Loop Detectors

Loop detectors are loops of wire installed beneath the track that create an inductive magnetic field. When a large metal object such as a railcar enters the loop, the field changes, triggering the presence signal.

Pros: Excellent stationary detection; integrates well with controllers; proven technology.

Cons: Installed in-track, so heavy track maintenance can damage them; not suitable for steel ties unless isolated; wires can deteriorate in flooding or prolonged water exposure.

Best for: Controlled yard environments with minimal track disruption.

Track Overlay Circuit

Track Overlay Circuits mount directly to the track and confirm the presence of an asset within the track section. Multiple sensors may also be used to indicate the direction of travel, making them ideal for AEI systems.

Pros: Can detect both stationary and moving railcars; compact and low-power; good for remote sites.

Cons: Not suitable with steel ties unless isolated; not recommended in frequent flooding areas; requires rail contact for detection.

Best for: Sites needing both stationary and moving detection in low-maintenance environments.

Radar Detection

Radar presence detectors emit a signal and detect reflections to determine if something is within their field of view. They are typically mast-mounted and positioned to cover a detection zone alongside the track.

Pros: Non-contact detection; unaffected by steel ties; works well in a variety of weather conditions.

Cons: Detection area must remain clear of obstructions; performance can vary depending on sensor design; generally best for motion-triggered presence confirmation.

Best for: Gate entrances or exits, or areas where in-track installation is not feasible.

Choosing the Right Detection System for Your Site

Before deciding, ask:

Do I need to detect stationary cars, moving cars, or both?

What type of ties are in place: wood, concrete, or steel?

Is flooding, debris, or heavy maintenance common on this track?

Can I mount equipment on a mast, or do I need in-track detection?

By weighing environmental factors, maintenance schedules, and operational goals, you can choose the presence detection that will deliver the most reliable performance for your AEI system.

Feature Comparison

Final Thoughts

Your AEI system’s accuracy depends on selecting the right presence detection technology for your site. Whether you are working in a controlled yard, a remote location, or a busy interchange, COMET can guide you to the best solution by factoring in site conditions, operational requirements, and long-term maintenance considerations.

FAQs

What is the difference between motion detection and presence detection?

Motion detection senses movement, while presence detection confirms that an object is still in place. In AEI, presence detection is critical to ensure all subsystems are ready and continue to capture data, from the locomotive to EOT to reliably provide a full train consist every time.

Can I use a motion-only sensor to detect stationary railcars?

No. Motion-only sensors, such as many radar-based units, are not designed to hold a detection signal once the railcar stops.

Which sensor works best in remote locations?

Track overlay circuits are a strong choice for remote sites due to their compact size and low power needs.

Do loop detectors require additional equipment?

Yes. Loop detectors typically work with a presence controller to relay detection data to your AEI system.

What if my site has steel ties or frequent flooding?

Steel ties can interfere with loop detectors and track overlay circuits unless isolated. Flood-prone areas may damage in-track wiring, making radar a better option.

www.cometind.com