railway-international.com

26

'25

Written on Modified on

igus unveils drylin W hybrid roller bearing for heavy-duty precision

igus launches lubrication-free drylin W hybrid roller bearing, supporting 7.5kg per point, withstanding 2,100N loads and 76,923 double strokes.

www.igus.eu

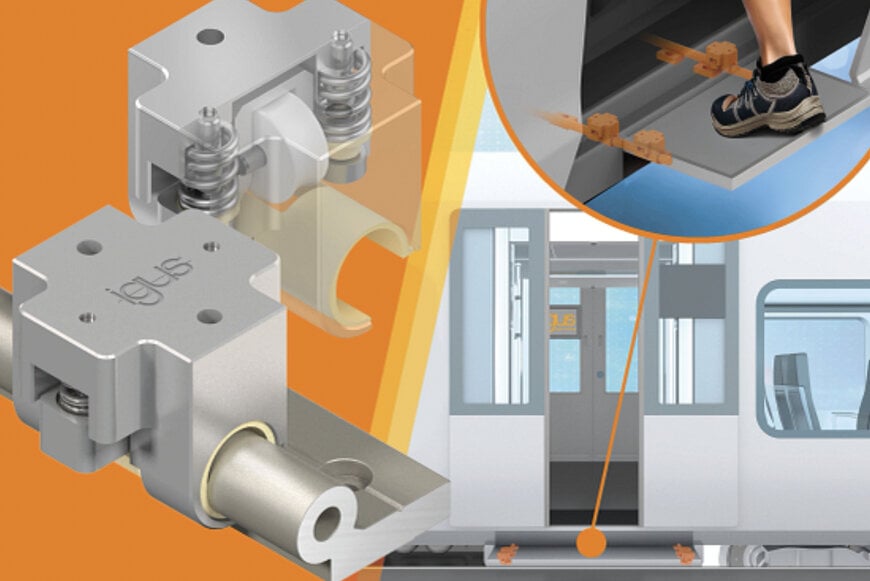

The lubrication-free and wear-resistant hybrid roller bearing combines smooth running with high load capacity. It is ideal for precise adjustment tasks under varying loads, e.g. for steps in train carriages. (Source: igus GmbH)

Many design engineers are familiar with the problem: they want a particularly smooth-running guide for pull-out mechanisms that can withstand high loads without wearing out quickly. Examples are retractable steps in train carriages, plinth solutions in the furniture industry or laboratory equipment. Classic lubricated metal ball bearings are out of the question as they require too much maintenance and are not sufficiently weather-resistant. It is precisely for this application that igus has developed the new hybrid roller bearing with roller retraction system for the drylin W series. Thanks to its crafty design, it combines smooth operation with heavy duty.

The dual functionality of the hybrid roller bearing – smooth and robust – results from its special design: the bearing consists of an aluminium housing in which a skate wheel is guided. A compression spring presses this roller against the guide rail with a defined pretension. A plain bearing made of robust high-performance plastic is also integrated into the housing. When a linear carriage moves unloaded over four hybrid roller bearings on a guide rail, the rollers bear the movement. This means that objects mounted on the carriage, such as the step of a train carriage, can be adjusted in a particular smooth way and with minimal friction, with a load of up to 7.5kg per bearing point.

Like a tortoise that pulls in its head in the event of danger

If a high load suddenly occurs, for example due to the body weight of a passenger, the pretension of the spring is overcome. The roller lifts off the guide rail, retracts into the housing and is thus protected against punctual overloading. This is comparable to a tortoise that pulls in its head in the event of danger. The main force is now absorbed via the wide load-bearing surface of the polymer plain bearing, which is in direct contact with the guide rail. After load removal, the roller takes over again. “This combination makes it possible to combine extremely smooth running with the temporary support of high loads (up to 2,100N) without wearing out the hybrid bearing’s sensitive skate wheel,” explains Michael Hornung, Product Manager for drylin Linear and Drive Technology at igus. “Applications are therefore much more fail-safe and require less maintenance.” The new hybrid roller bearing is now available in installation size 16. Upon request, igus can supply the bearings ready for installation in a WWH-series roller carriage with a corrosion-resistant aluminium plate for superstructures. The hybrid roller bearing can be used, among other things, as an adjustable plinth solution, whether as a step, conductor replacement or in the seating area for the furniture industry. It is also found in yacht construction and shipbuilding, laboratory equipment and the growing market for mobile homes and tiny houses.

Hybrid roller bearings withstand 76,923 double strokes

igus has proven the durability of the new roller bearings in the test laboratory. Experts at igus moved a linear carriage with four bearings on a rail that was 1,500mm long and had a weight of 250N per bearing point. The result: the carriage achieved 76,923 double strokes before reaching its wear limit. The lubrication-free nature of the igus high-performance polymers also contributes to the system’s reliability. Thanks to integrated solid lubricants, the hybrid roller bearings do not require lubricating oil or grease, which could make the movement less smooth and increase maintenance costs due to contamination. Unlike with metal bearings, there is also no risk of corrosion. This makes the solution ideal for outdoor use in all kinds of weather.

You can find more information about the drylin W hybrid roller bearing here.

www.igus.com

Many design engineers are familiar with the problem: they want a particularly smooth-running guide for pull-out mechanisms that can withstand high loads without wearing out quickly. Examples are retractable steps in train carriages, plinth solutions in the furniture industry or laboratory equipment. Classic lubricated metal ball bearings are out of the question as they require too much maintenance and are not sufficiently weather-resistant. It is precisely for this application that igus has developed the new hybrid roller bearing with roller retraction system for the drylin W series. Thanks to its crafty design, it combines smooth operation with heavy duty.

The dual functionality of the hybrid roller bearing – smooth and robust – results from its special design: the bearing consists of an aluminium housing in which a skate wheel is guided. A compression spring presses this roller against the guide rail with a defined pretension. A plain bearing made of robust high-performance plastic is also integrated into the housing. When a linear carriage moves unloaded over four hybrid roller bearings on a guide rail, the rollers bear the movement. This means that objects mounted on the carriage, such as the step of a train carriage, can be adjusted in a particular smooth way and with minimal friction, with a load of up to 7.5kg per bearing point.

Like a tortoise that pulls in its head in the event of danger

If a high load suddenly occurs, for example due to the body weight of a passenger, the pretension of the spring is overcome. The roller lifts off the guide rail, retracts into the housing and is thus protected against punctual overloading. This is comparable to a tortoise that pulls in its head in the event of danger. The main force is now absorbed via the wide load-bearing surface of the polymer plain bearing, which is in direct contact with the guide rail. After load removal, the roller takes over again. “This combination makes it possible to combine extremely smooth running with the temporary support of high loads (up to 2,100N) without wearing out the hybrid bearing’s sensitive skate wheel,” explains Michael Hornung, Product Manager for drylin Linear and Drive Technology at igus. “Applications are therefore much more fail-safe and require less maintenance.” The new hybrid roller bearing is now available in installation size 16. Upon request, igus can supply the bearings ready for installation in a WWH-series roller carriage with a corrosion-resistant aluminium plate for superstructures. The hybrid roller bearing can be used, among other things, as an adjustable plinth solution, whether as a step, conductor replacement or in the seating area for the furniture industry. It is also found in yacht construction and shipbuilding, laboratory equipment and the growing market for mobile homes and tiny houses.

Hybrid roller bearings withstand 76,923 double strokes

igus has proven the durability of the new roller bearings in the test laboratory. Experts at igus moved a linear carriage with four bearings on a rail that was 1,500mm long and had a weight of 250N per bearing point. The result: the carriage achieved 76,923 double strokes before reaching its wear limit. The lubrication-free nature of the igus high-performance polymers also contributes to the system’s reliability. Thanks to integrated solid lubricants, the hybrid roller bearings do not require lubricating oil or grease, which could make the movement less smooth and increase maintenance costs due to contamination. Unlike with metal bearings, there is also no risk of corrosion. This makes the solution ideal for outdoor use in all kinds of weather.

You can find more information about the drylin W hybrid roller bearing here.

www.igus.com