railway-international.com

10

'26

Written on Modified on

ABC of freight transport – S for switch

DB Cargo explains how switches underpin reliable rail freight operations, especially at busy nodes and under challenging winter conditions.

www.dbcargo.com

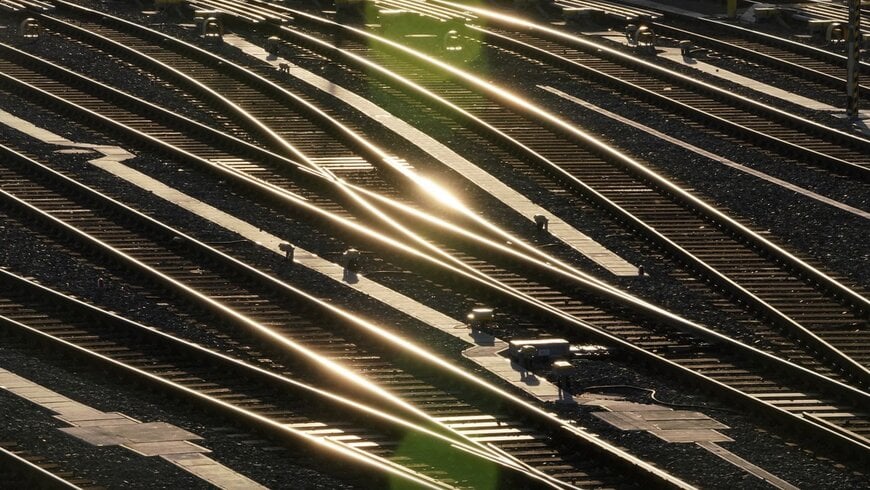

In rail freight transport, the reliable operation of switches is critical for routing trains through junctions, yards and terminals, enabling flexible operations even under high traffic density and winter conditions.

Switches as a foundation of rail operations

When trains navigate complex junctions, marshalling yards and terminals with multiple parallel movements, switches are a decisive factor. They direct trains, enable route setting and allow track infrastructure to be used efficiently. As such, switches are among the most operationally critical and technically demanding components of rail infrastructure.

Each switch combines movable tongues, precise setting and locking mechanisms and components exposed to high mechanical loads. Reliable interaction between technology, operations and maintenance is essential, particularly in freight transport where long, heavy trains and tight schedules leave little tolerance for disruptions.

More than a change of direction in freight transport

In freight operations, switches play a broader role than simply diverting trains from one track to another. They enable shunting movements, train formation and access to industrial sidings, ports and terminals. As a result, the condition and availability of each switch directly affect the performance of an entire facility.

At heavily used locations, switches determine whether parallel movements can be executed and whether operational processes remain stable. High availability ensures flexibility in routing and supports predictable operations, while failures can quickly lead to bottlenecks or standstills.

Winter operation as a critical stress test

Winter weather places additional strain on switches. Snow, ice and rapid temperature changes directly affect tongues, frogs and control areas. Because switches are movable elements, they are particularly sensitive to freezing and contamination.

To maintain availability in winter, rail infrastructure relies on coordinated winter operation concepts. These combine technical solutions with operational procedures and targeted maintenance activities. The objective is to ensure that switches remain functional even during frost and snowfall, supporting continuous freight operations.

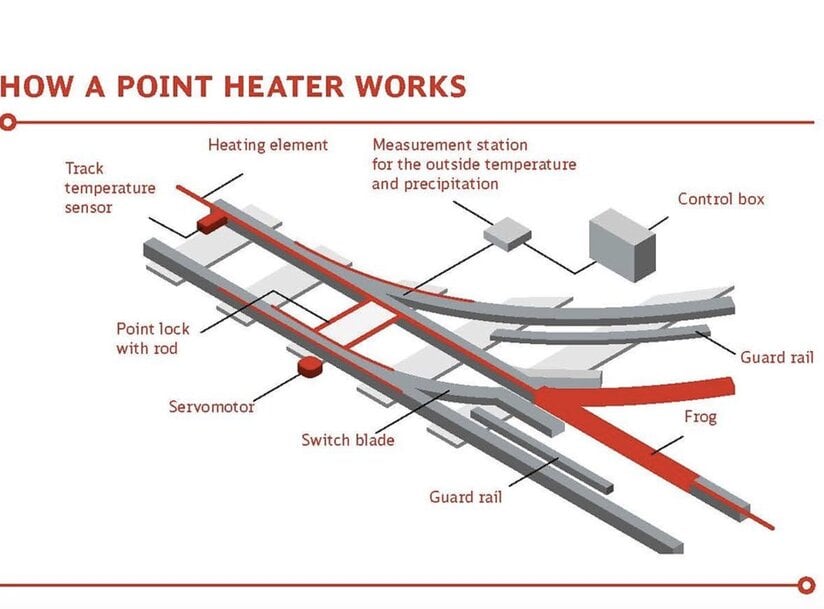

Schematic representation of a point heating system: Heating elements along the points and stock rails prevent snow and ice from freezing. Temperature and weather sensors control operation as required within the framework of the winter concept.

The role of switch heating

A key technical element in winter operation is switch heating. Heating systems are installed at locations where switch availability is particularly critical, such as junctions, marshalling yards and heavily trafficked lines. Their purpose is not to clear tracks of snow, but to prevent ice and snow from impairing the movement of critical components.

Modern electric switch heaters operate automatically based on weather conditions. Sensors detect temperature and precipitation, and control systems activate heating as required. Not all switches are equipped with heating; instead, a combination of targeted heating and established maintenance routines ensures reliable winter operation across the network.

Operational benefits for rail freight

For freight transport, dependable switches translate directly into stable processes. Signalers can set routes reliably, dispatchers can plan operations with confidence, and train drivers benefit from predictable infrastructure conditions.

This reliability is especially important in complex operating environments, where efficient use of track systems depends on the availability of switches. Even during winter, functional switches support continuous transport chains and help maintain service quality.

Toward smarter switch management

As digitalisation advances, switches are increasingly integrated into condition-based monitoring systems. Data such as setting cycles, operating parameters and technical states can be recorded and evaluated centrally. This supports predictive maintenance and more targeted interventions.

Switch heating systems are also evolving, with more intelligent control strategies aimed at reducing energy consumption while maintaining availability. These developments help ensure that switches continue to perform their central role in freight transport—often unnoticed, but essential for stable, efficient and resilient rail operations.

www.dbcargo.com