A major Belgian rail link re-electrified using a technology never seen before in Europe

In just 3 weeks of traffic interruption, a 66km section of the "Brussels-Luxembourg" rail link will be switched from 3kV DC to 25kV AC.

As part of the priority trans-European projects established by the European Commission, the Belgian Government and the Walloon Region decided in 2006 to undertake major upgrading work on the railway lines connecting Brussels and Luxembourg. This project aims to improve the competitiveness and profitability of rail by increasing the reference speed. This will be achieved through, among other things, the replacement of the electrical installations and the introduction of a more efficient 25kV power supply system. To limit the impact on traffic, TUC RAIL, a subsidiary of the Belgian infrastructure manager Infrabel, is using a mixed "3kV - 25kV" catenary technology that is unprecedented in Europe!

A 175 km long "Axis 3" to be modernised

This project, one of the most ambitious on the Belgian railway network, is called "Modernisation of Axis 3". It extends from the outskirts of Brussels (Louvain-la-Neuve junction in Ottignies) to Arlon, a distance of 175 km. The project has been entrusted to TUC RAIL, a subsidiary of the infrastructure manager Infrabel, which specialises in the construction of new railway infrastructures and the adaptation and modernisation of existing ones.

This "Modernisation of Axis 3" plans to replace outdated equipment (tracks, signalling, catenaries) and facilities whose gauge is now too narrow (bridges, tunnels). It also includes complete re-electrification, as most of the current power supply components, including the 3kV DC substations, are outdated.

The need for greater electrical power became apparent as this work is part of a desire to increase the speed, load, and frequency of rail traffic.

Mixed catenary 3kV DC/25kV AC

In 2010, the decision was made to move towards a 25kV AC catenary power supply by installing a mixed "3kV DC/25kV AC" catenary, i.e. "3kV direct current and 25kV alternating current". This temporary dual-voltage solution, which is unprecedented in Europe, aims to limit the impact on traffic throughout the electrical installation replacement project. Its totally innovative aspect lies in the possibility of quickly switching from one voltage to another. This required years of study and integration into an existing infrastructure that remained in service.

The voltage changeover will be the most demanding phase for the teams in the field. Therefore, the total closure of line 162 for a limited period of three weeks - which is a real feat - has been scheduled from the evening of Friday 5 August to the morning of Monday 29 August. It has been planned in such a way as to maintain rail traffic to a maximum at the two major stations in service (Arlon and Libramont) and at the SNCB workshop.

This exceptional closure will require a great deal of technical and human resources. Around 100 people, four locomotives and six "rail-road" type machines will be mobilized 24 hours a day.

Organisation of the work

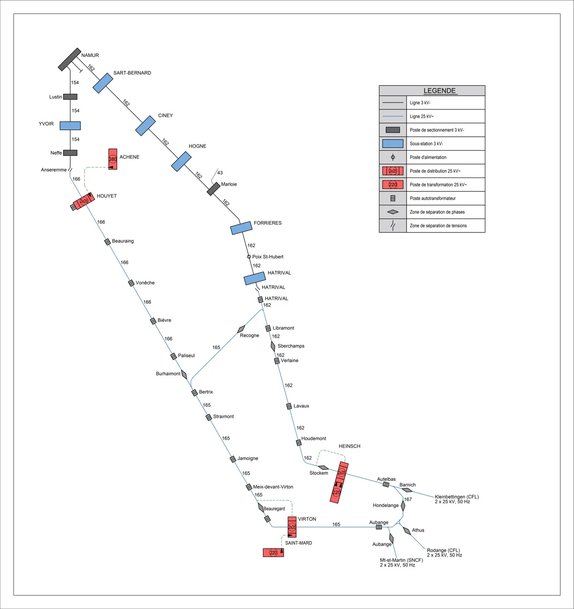

Infrabel took advantage of the general voltage change in Luxembourg in 2018 to switch a 2 km "test" section between the Luxembourg border and Barnich to 25kV AC. The next step is to increase the voltage from the Luxembourg border to Namur in two major shifts. The first, between Barnich and Hatrival - a distance of 66 km - is therefore imminent. The second, between Hatrival and Jambes (south of Namur) - this time a distance of 85 km - is scheduled for 2029.

The "Barnich-Hatrival" phase is planned to take place in three steps:

- The replacement of the catenary equipment which involves removing the current compound catenary and building a new one. This phase is carried out in sections of +/- 10 km, which represents an average section between two switch zones, allowing trains to be diverted. In this way, traffic is maintained during the work. The old sectioning is being retained as the line continues to be operated at 3kV DC. These works are being carried out in parallel with the rectification of the route, the replacement of rail-sleepers-ballast, the widening of the platform and the replacement of the signalling.

- Once the section is fully equipped with the new catenary, a "preparation of the 25kV sectioning" phase will begin. This work (installation of dozens of switch-disconnectors along the entire section, installation of power supplies at the auto-transformer stations and the traction substation, and installation of the neutral zone that will separate the 25kV AC and 3kV DC power supplies) is being carried out mainly at night.

- The last phase concludes the work with the "Switch" operation. The tracks will be completely cut off. The work will be carried out in barely three weeks and involve disconnecting and removing the 3kV switches and then connecting the 25kV switches to the catenary, removing the devices specific to direct current (carrier-feeder connections, surge protectors) and interconnecting the earthing and rail earthing devices (in 3kV, the rails are used as a return circuit for traction current).

The advantages of 25kV

In addition to a higher power rating allowing increased traffic, a 25kV AC upgrade has many advantages. A single substation can supply long sectors (from an injection point to a voltage separation or phase separation zone). The maintenance costs for 25kV AC substations are lower. Working at a voltage much higher than 3kV DC also limits line losses and is therefore more efficient and less expensive. The much more limited traction currents allow the use of a lighter, and therefore less expensive catenary.

The 25 kV AC power supply system is not a first on the Belgian railway network. It can be found on the four high-speed railway lines, the "Rivage-Gouvy" railway line and the international "Athus-Meuse" railway line since its electrification in the early 2000s. Infrabel's neighbours (SNCF and CFL) have also opted for 25kV AC voltage on all or part of their network (CFL converted the last remaining 3kV catenary section (Luxembourg - Kleinbettingen) in 2018).

Consequently, in addition to having a new 25kV substation at Heinsch, with a high degree of availability and reliability, the "Namur-Luxembourg border" railway line can also receive power if necessary, from the CFL or the "Athus-Meuse” railway line (via the 167 Aubange-Autelbas railway line or the 165 Bertrix-Libramont railway line).

Certification: a guarantee of mobility, quality, and safety

All the work is evaluated by a Notified Body. These inspections cover the design, execution and testing phases. At the end of this evaluation, the Notified Body will issue an EC certificate of conformity at the end of this year, which will attest to the conformity of the new 25kV AC power supply system with European regulatory requirements: the Technical Specifications for Interoperability (TSI).

The interoperability of the rail system is the ability for any certified rolling stock to operate on any rail network without distinction. Harmonised European regulations provide a common framework, eliminate national differences between rail networks and facilitate cross-border travel for both passengers and freight. This network harmonisation increases the safety of the European railway system insofar as it sets common requirements for all member states for the criteria and constituents that have an immediate impact on safety.

The EC certificate of conformity will allow Infrabel, the infrastructure manager, to draw up the EC declaration of conformity, which attests to the interoperability of the system concerned.

www.infrabel.com